SILICONE RUBBER COMPOUNDS (VMQ and FVMQ)

Silicones and fluorinated silicones

Commonly referred to with the acronyms VMQ and FVMQ, silicones and fluorinated silicones are long-chain polyorganosiloxanes that differ from each other with their diverging natural characteristics.

Thanks to their elasticity, chemical and thermal resistance, food compatibility and high biocompatibility, VMQs are widely used in many applications. Production of items in contact with food and drinking water vessels are often produced using this material. The homologous family of fluorinated products, fluorosilicones, on the other hand, stand out for their exceptional thermal resistance (up to 300°c) and resistance to oils and hydrocarbons, characteristics that have allowed FVMQs to become one of the most commonly-used materials in the production of turbo charge hoses and automotive gaskets.

The variability of peroxide and platinum accelerators also allows us to employ different types of process. Continuous and discontinuous extrusion, calendering, injection molding, compression molding are the major technologies used for the transformation of silicone and fluorosilicone compounds and the obtaining of finished articles.

LTE Italy produces VMQ and FVMQ thanks to a technologically-advanced production area.

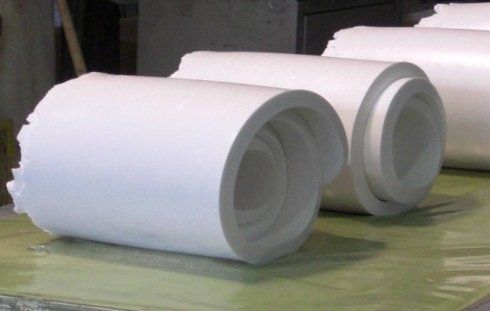

Divided by type and colour, the compounds are produced on five dedicated mixing lines and a filtering line with gear pump for a production capacity of 260Tonne/month. Thanks to the versatility of the mixing area, it is possible to supply the compounds in different formats such as continuous talc strips, strips wrapped in PE, sheets, rolls and bricks of various sizes.